If it’s a long bobbin for a Vibrating Shuttle machine, it’s easy – you hold the shuttle with the pointed end down, and the bobbin drops into the top of it with the thread coming off from left to right across the front. If the thread’s coming off from the back of the bobbin, that’s wrong. It needs to be left to right, on your side.

Yes, I know a picture would have been a great help there, but I forgot to take one. At this time of year I have to wait for a bit of sunshine in which to take a halfway-decent snap, and more often than not as soon as we get the slightest hint of a blue sky, Elsie drags me into the garden to be her assistant/labourer and by the time I get back inside, put the kettle on and remember there’s a picture I need to take, the sun’s gone in.

Anyhow …

If it’s a round bobbin machine, it depends on what model it is, and if you’re thinking to yourself “does it matter which way round I put the bobbin in?”, the answer is oh yes it does.

Now obviously this isn’t a problem if you only ever use one type of vintage Singer, because you’ll have read the book of words for it and know perfectly well which way round the bobbin goes in it. But what if you’ve just scrounged the lovely old 66K that Mrs Thing next door but one was about to take to the dump along with her weekly accumulation of empty gin bottles and copies of the Daily Mail and you can’t wait to see if it works? Or your friend Sally of the School Gate Gang’s got an old Singer which won’t sew properly and she’s asked if you’ll have a look at it for her if there’s coffee and cupcakes involved? Maybe you have a 99 and a 201 and every now and then you have a brainfart about the bobbins? Whatever, here’s how you tell which way round the bobbin goes in a pre-mid-1960’s Singer (and for all I know about the later machines, in one of them too).

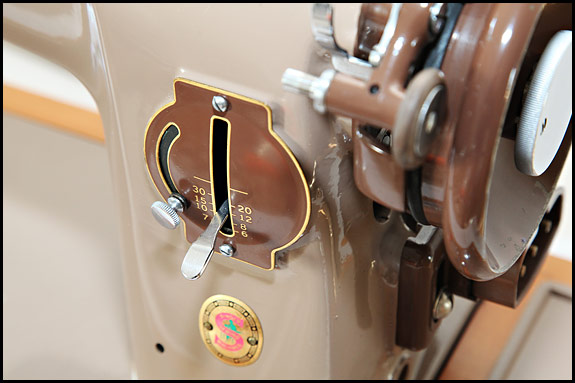

Check out the bobbin case, which is the proper name for that bit of your machine into which you drop your bobbin. If you look round the sides of the hole into which your bobbin goes, you will see a diagonal slot in it, like this …

That’s a 66/99 bobbin case (they’re identical), and as you can see, the slot exits the case to the left, or to put it another way, anti-clockwise.

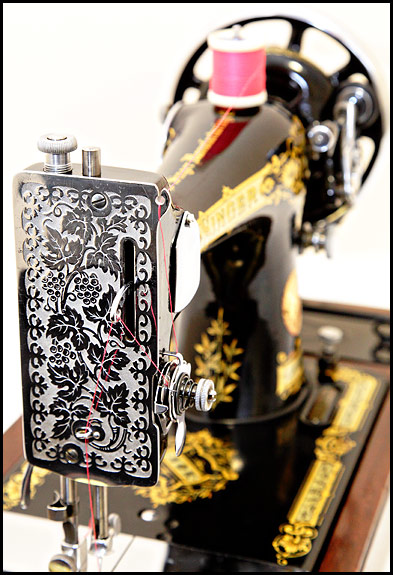

And there’s that same bobbin case photographed from the same angle, now with a bobbin in it the right way round i.e. with the thread coming off it anti-clockwise. Yep, the thread comes off the bobbin the same way that the slot exits the case.

Having got the bobbin in, your next step of course is to pull the thread to the right so it runs under the tension spring and into the notch, then pull it across the top of the bobbin and close your slide plate.

When you do that, you’re actually making sure that the thread leaves the bobbin through the hole at the bottom of the slot, then under the tension spring in exactly the right way for the spring to apply constant tension. Pulling on the thread pulls it down the slope of the slot, and ensures that it stays in the hole as it feeds off the bobbin.

If your bobbin is in the wrong way round, pulling on the thread doesn’t necessarily slide it down the slot into the hole, so you may well get inconsistent bottom tension.

Now here we have the bobbin case out of a 201, and as you can see, the slot faces the other way i.e. it exits the case to the right, or clockwise. So which way does the thread need to leave the bobbin on a 201?

Yep, that’s right. Clockwise. OK, I completely forgot to photograph a 15 bobbin case, but you can take it from me that it has a slot in it which provides exactly the same clue as to which way round the bobbin goes.

And that’s it. All you need to do is take a look at the slot in the side wall of the bobbin case, and that tells you which way your thread needs to leave the bobbin …

66/99 on the left, slot exits anti-clockwise therefore thread comes off the bobbin anti-clock. 201 on the right, slot exits clockwise, so your thread comes off clockwise too, like this …

Finally, just in case it hasn’t occurred to you, if you take this information together with what I’ve rabbitted on about in earlier posts, you now know how to put both the needle and the bobbin in any vintage Singer the right way round, as well as which way to thread the needle – and all this without an instruction book.

And by the way, if you’re still tut-tutting about these grotty old bobbin carriers, you should have seen the state of them before Elsie insisted on getting the thick of the muck off …

You must be logged in to post a comment.