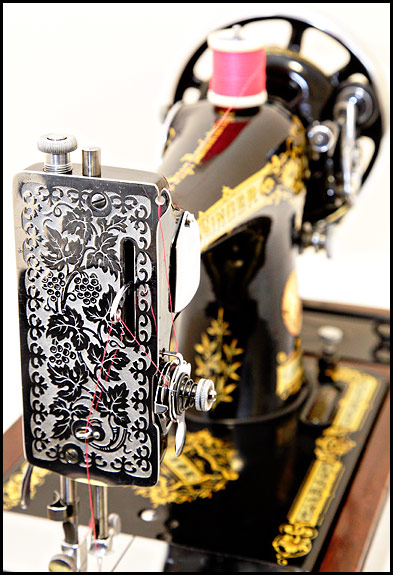

Here’s a picture of the drive end of Elsie’s old faithful 27K, which was made in 1900 and still resides in the ornate drawing room cabinet* in which it left the shop 112 years ago.

Now, if you’re really into the old Singer stuff, I bet you got as far as “made in 1900” in that sentence and immediately said to yourself “Ahah! So it hasn’t got a boss for a handcrank!”. And if you did, I bow down before your awesome knowledge of such arcane stuff.

If you didn’t, and you’re not entirely sure what a “boss” is in this context anyhow, look closely at the right-hand side of the column of this particular 27K, and hopefully you’ll be able to see that there isn’t the usual sticky-outy bit to which a hand crank or indeed a motor can be fitted. That’s the “boss”, or rather it would be if this machine had one. Later 27K’s do have one, but only a real vintage Singer geek could tell you when they changed from bossless to bossed. The best I can do is say that in 1900 at least some 27K’s didn’t have a boss but by 1903 they all did.

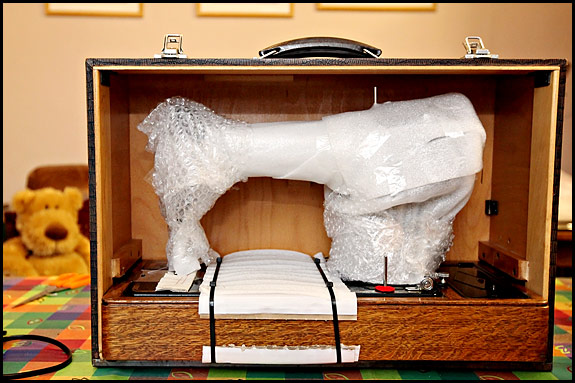

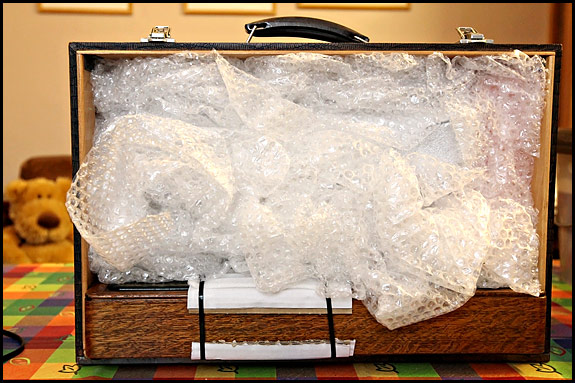

So, should you wish to fit a hand-crank to one of these fine old treadle machines, how might that be done when there is no apprarent means of attaching one? In theory it’s easy – all you need is Hand Attachment 81712, as shown below together with a bobbin winder assembly which wanted to be in the picture too …

Once you have your Hand Attachment 81712 to hand, as it were, it’s simply a case of undoing one screw and removing the belt guard from your early 27K, then fitting the handcrank by clamping its mounting bracket round the collar onto which the belt guard was originally fixed. It’s a job which requires nothing more than one ordinary screwdriver and five minutes of your time.

The problem is of course that you first need to acquire your Part No. 81712. Which was only made for the very early 27K. And then apparently not in any great quantity. So they’re a bit thin on the ground. I’ve no idea how many of them Singer actually made, but I do know that the Hand Attachment had been officially declared obsolete by 1906, so it’s perhaps not surprising that 105 years later, most folk have never heard of it. Certainly this is the only one that Elsie and I have ever actually laid hands on.

Given its rarity, it’s got to be a symptom of something or other that having completely forgotten we had this one, I found it yesterday under a pile of stuff alongside the dead printer which I’d finally decided to take down to the dump recycling centre. Be that as it may, given that Elsie’s 27K in the drawing room cabinet is in its original state and it’s such a delight to treadle, there’s actually more chance of me mastering the art of knitting than there is of us ever needing to use this particular bit of kit, therefore one complete Hand Attachment 81712 is now listed on our Bits ‘n’ Bobs page!

So now somebody, somewhere is wondering “OK, that takes care of a handcrank, but how do you fit a motor?”. The answer to that is “with great difficulty”, which as far as I’m concerned is just as well because I really can’t imagine why anybody might want to vandalise a very early 27K by motorising it …

And … just as I was about to publish this post, an email came in from Lulu alerting me to a listing on Ebay UK of a rather unusual treadle machine …

I was interested to see that the drawer pulls on this one are different to those on Elsie’s early drawing room cabinet, and that the mat on the treadle plate is a different design too. The real surprise though is the 28K. I’ve never seen a 3/4-size machine of any flavour in a drawing-room cabinet before. It’s obvious from the other pictures in the listing for this one that it’s a DIY job and an old one at that, but I can’t see why it wouldn’t work just fine. And I love the way the handcrank’s still on it …

* If you’re in the US of A, for “drawing room cabinet” read “parlor cabinet”.

Edited 2nd October to add – thanks to Linda and Heather, I now know that Singer did indeed supply the 28K in a Drawing Room Cabinet!

You must be logged in to post a comment.