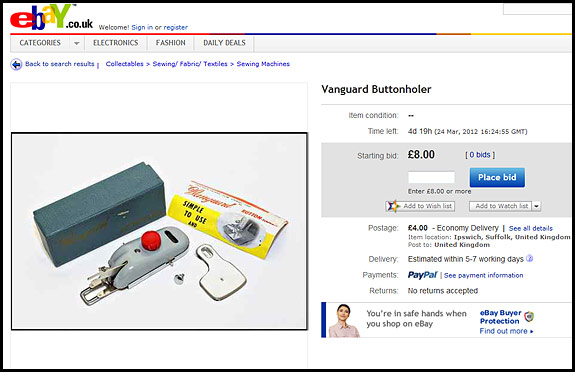

Somebody asked me the other day what a “Jetson buttonholer” is or was, and I said I’d do a post about it. So here we go.

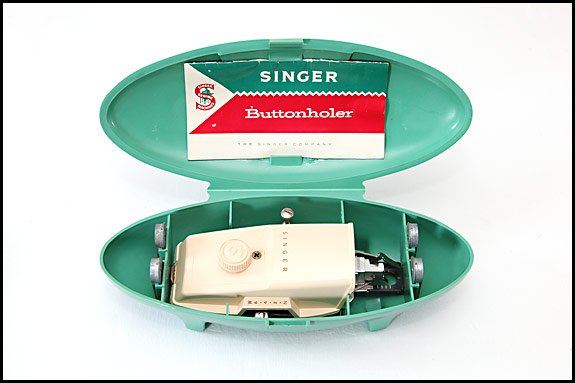

That green thing is what is commonly referred to as the Jetson case – so called after the green spaceship in “The Jetsons”, an early 1960’s American television cartoon. In it is contained the Singer Buttonholer489510, its four alternative templates, the fixing screw and the feed dog cover plate (hiding under the buttonholer itself) …

There’s also a sort of muddy dark pink version of that case, in which should be found the Buttonholer489500, which is identical except it’s for slant-shank machines. And the answer to the question “if the buttonholers are identical, how do you tell them apart?” is that in the absence of a part number on it, the straight-shank one says “STRAIGHT” on top of the metal near where it fits onto your presser bar, and the slanty one says “SLANT”.

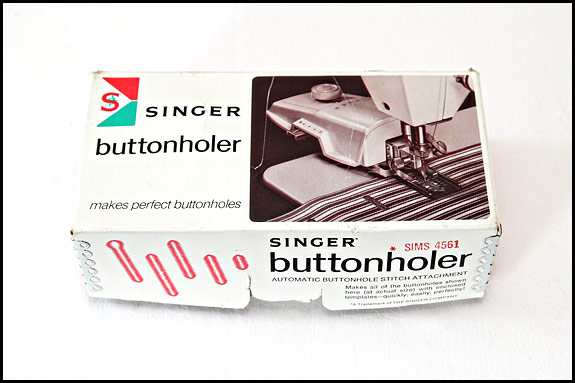

Note that those templates are metal, and that they’re exactly the same as those for the Buttonholer 160506 (the nice black one in the dark green textured plastic case). However, you only got your Buttonholer 489510 in that Space Age case if you bought it in the States! Here in the UK, we got the cheapo packaging …

We also got plastic templates instead of the metal ones …

So. Which would you have preferred?

Thought so.

Anyhow, that’s the Jetson thing done, and it’s reminded me to point out that I put some more goodies on the Bits ‘n’ Bobs page yesterday. They’re mixed in with some of the stuff that’s been there a while (including a Buttonholer 489510), so do scroll down and have a nosey.

On the home front, things are hotting up now even if the weather isn’t. The rhubarb’s all coming along nicely, the greenhouse is crammed full of green things all a-growing, Elsie hoed the spuds up in the garden for the first time yesterday, and she picked the first radishes of the year. We seem to be about a week away from the start of the home-grown lettuce, although everything’s a few weeks behind last year. We bottled our first rhubarb on April 15th last year, but it’s going to be a good fortnight or so before that happens this year.

One thing that has already happened though is The Brewing Of The Nettle Beer …

Doesn’t that look scrummy? Actually I don’t think so either, but Elsie does. That’s the first gallon (less half a pint taken for quality control purposes), sitting quietly in a bucket in the bathroom yesterday, and seeing as how you’re now bound to be seized with a sudden urge to make some yourself, here’s the secret recipe …

Fill a supermarket carrier bag with young nettle tops, take them home and wash them. Chuck them in your preserving pan or similar and add enough water to cover, taken from one gallon. If you fancy spicing it up a little, add a tablespoon or so of chopped root ginger. Maybe even a pinch of Cayenne pepper too, although Elsie makes it without either.

Bring to the boil and simmer for 15 minutes. It will smell foul (no it doesn’t, it smells like spinach -E) and it will look disgusting.

Remove from heat, fish out nettles, add juice of 2 lemons, a tablespoon or so of cream of tartar and 1lb brown sugar and stir well until dissolved.

Add the remainder of your gallon of water.

When cooled to body temperature, add about half a teaspoon of beer yeast and stir. If you don’t have beer yeast, use wine yeast instead. If all you have is ordinary baker’s yeast, try that and let us know how it works.

Now, if you’re into home brewing, pour into a fermenting bin and carry on like you do for proper beer. If you’re not, pour into clean PET bottles and leave for 5 days before sampling.

The pressure will build up sooner than you might think, so be sure to keep an eye on the bottles. If they start bulging, let a bit of the pressure off 2-3 times a day if needed, but don’t overdo it or you’ll lose the fizz.

We’ve never yet had a bottle burst or blow the cap off, but we always let it do its thing in a bucket in the bathroom and throw an old towel over just in case …

You must be logged in to post a comment.