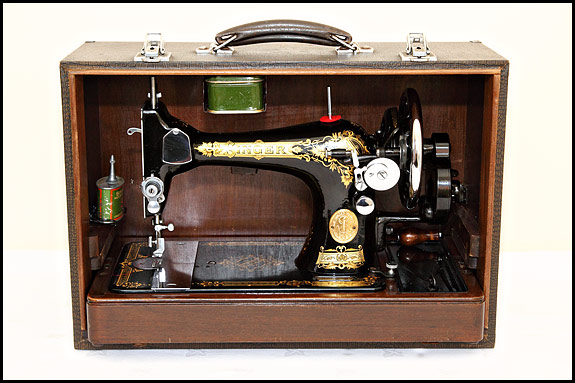

Diane asked this morning what she ought to do about tickling the tappets of her late granny’s Singer 27K which she’s just rediscovered. The machine still works, so there’s obviously nothing drastically wrong with it, and Diane’s done the sensible thing and downloaded a copy of the book of words, so the question is – should she be doing anything by way of essential maintenance before she starts doing some serious sewing with it for the first time in 40 years?

Well, in my opinion the short answer is “not a lot really”. I’d start by tilting it back in its base and seeing what the underneath’s like. If it’s covered in oil and fluff, an old paintbrush will get rid of a lot of that, but if you really want to go to town, a bit of paraffin or a squirt of WD40 on a rag should shift anything you don’t like the look of. One thing to watch though when you tilt it back on its hinges is that the whole lot doesn’t tend to roll over onto its back, which can lead to fun times if it does – especially if it’s come loose on the hinges. And beware of old rusty pins and bits of broken needles whilst furtling about under there. Once you’ve got rid of anything really oily or a bit yukky underneath, get the Hoover out, but before you attack it here’s a couple of tips.

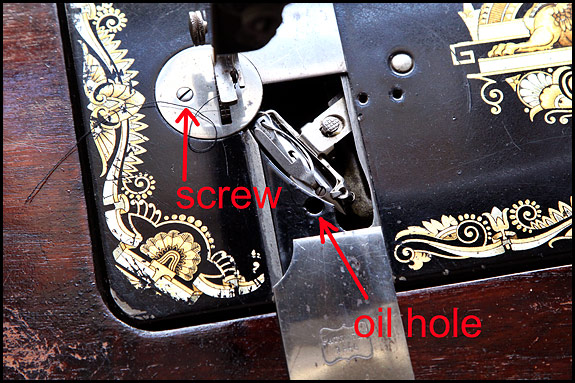

First off, if you open the bobbin plate, you will see the hole shown in this snap …

Either that hole will have nothing in it except general grot, or it will have a plug of felt which may or may not be oily. Odds on it isn’t oily. If it does have a plug of felt, that will probably be a very nondescript colour and may not even be recognisable as felt, but if it’s level with the top of the hole it usually is. That’s an oil wick, and it’s referred to in the manual. The picture above is the bobbin area of Cleo, Elsie’s 27K treadle machine from 1900, and Cleo is feltless on account of I haven’t got round to putting a new one in. It’s been on my list for ages and it will happen one day, but Elsie is wisely not holding her breath.

My point is (hey, we got there) that if there’s something in that hole and you reckon it looks like a felt plug, be sure to put your finger over it before applying the nozzle of your vacuum cleaner. If you don’t, you will soon feel a bit of a silly and wish you had. And don’t ask how I know that.

The second tip concerns the needle plate, under which live the feed dogs, which tend to accumulate fluff. If you have a screwdriver which fits the needle plate screw (labelled above) properly, have a go at unscrewing it while pushing down fairly hard on the screwdriver so it doesn’t chew up the slot in the screw. If it doesn’t want to turn fairly easily, either you’re turning the screwdriver clockwise when you should be turning anti-clock or it’s being awkward. If it does start unscrewing, take it out, take the plate off and do your thing with the Hoover (but don’t suck the screw up it) before replacing it. If the screw doesn’t want to play, stick your tongue out at it and don’t worry about the fluff for now.

After that, all I would do is follow to the letter what it says in the book about routine oiling, then make yourself a nice cup of tea before knocking up a quick copy of Kate Middleton’s wedding dress for next door’s eldest.

I’m assuming, by the way, that Diane’s Singer 27 is a hand-crank. If it’s a treadle, there’s a bit more to think about which I can cover in another post. If it’s been motorised, there’s not a lot you can actually do yourself to improve whatever state the motor’s in, especially when poking round wiring which is bound to be fairly brittle with age is never a good idea. It is a good idea to check the drive belt though, and to think about getting another before it goes the way of all drive belts. You can get the belts pretty much anywhere.

Finally, a warning. If you’re not familiar with proper sewing machine oil, be aware that it’s very “thin” and runny stuff. Newspapers under the machine and some kitchen towel in the bottom of the base is the rule here before we even get the oilcan out!

PS If you have an early 27 or 28 and you’re wondering why yours doesn’t have that round criss-crossed button thingy seen in the picture above at 2 o’clock to the shuttle, that’s because yours hasn’t been modified with the later shuttle lifter-upper like this one has …

You must be logged in to post a comment.