It’s a shame I didn’t think to take a few snaps of a machine we bought off Ebay last year from a bloke in Scotland. The seller assured me that he knew how to pack it, and what’s more had loads of bubble wrap, so it should get here safely and I needn’t worry. But of course it didn’t. The short story is that he’d wrapped a few bits of bubble wrap round the column and the arm, popped it into the suitcase-type case, wrapped that with one thickness of bubbles then basically just wrapped a carton round it. And he was a bit mean with the parcel tape too.

The nett result was a split wooden base and some nasty dinks in the finish of the machine itself. The split base was down to the parcel having ended up on its back in transit, which caused the head to pull the retaining catch out and try parting itself from the base on the side away from the hinges. And the dinks were caused by the metal tray which held the tin of attachments against the top of the case being pulled out on impact, leaving a heavy metal box free to rattle about against the machine. Writing “fragile” in small lower case letters with a blue biro in a couple of places on the brown cardboard outer had obviously not helped at all …

Here’s how we do it, but first off a statement of the obvious. Old sewing machines are heavy. They are in fact very heavy indeed. A 28 or a 99 in a suitcase-case type weighs 15kg. A MkI 201 in the same type of case weighs 21kg. And if you’ve never picked one up so you’re struggling to imagine how heavy 21kg might be, think bag of cement. Or bag of coal. Anyhow, they’re heavy. But alas, heavy doesn’t mean they can’t be damaged in transit …

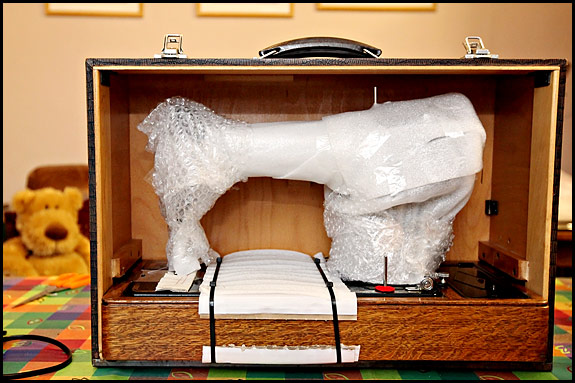

Here we see the start of the process. That’s a 201K MkI in that case and as you can see, Elsie’s started wrapping everything above the machine bed in bubble wrap and recycled plastic foam packing sheet. The bed is tied down to the wooden base with those heavy-duty black nylon cable ties, tightened down onto thick card packing so they don’t dig into and mark the woodwork.

At the stage shown above, all the space behind the upper part of the machine is packed out tight with whatever we have available, be it secondhand bubblewrap, plastic foam, bits of expanded polystyrene sheet or even crumpled up brown paper. Anything, in fact, except polystyrene packing beans, which are no use whatsoever for this application.

That orange on the right is the foot pedal and wiring, padded out then wrapped in several layers of packing tissue until it fits snugly between the column and the side of the case. Having got that in, we then lay the case on its back and check carefully that the machine doesn’t try to settle down if we push on it. If it does, we stuff more packing behind it until it doesn’t.

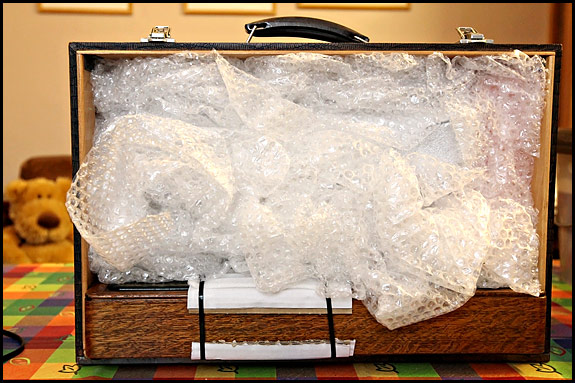

And that’s about as much packing as we could get in before the bit which is a real faff. Once we get to this stage, Elsie spends ages trying the lid on, taking it off, putting a bit more packing in, trying the lid again and so on, until we’re as sure as we can be that nothing’s likely to move inside the case unless it hits the ground at a bad angle when dropped from a considerable height.

Once the lid’s on, we can’t rely on the catches to keep it shut, so the case is tied shut with polypropylene binder twine going both ways round it. We then wrap the whole thing up with several layers of bubble wrap, a process which involves an enormous roll of bubble wrap and both of us on hands and knees on the kitchen floor. It must be quite entertaining to watch.

After that comes a carton, and this is where the expanded polystyrene beans come into their own. The case sits in the carton on a couple of inches of beans, then the space all round and on top of the case is packed tight with beans before I get to play with the parcel tape gun. After that comes the addressing, and, for what little good it does, the ritual “FRAGILE” and “THIS WAY UP” marking in upper case with a fat felt tip marker.

We’re not done yet, though. The last step is to get more binder twine and tie up the outer carton both ways, before crafting two thick twine hand holds on top of it. And before you start thinking how considerate it is of us to do that for the greater comfort of the poor blokes who will be handling this great weight, let me tell you it’s no such thing. It’s just another thing we can do to increase the odds on the carton remaining right way up for at least most of its time in transit.

So that’s how we do it. And having just written this post, we’ve now sold a machine which is going down to Cornwall by courier on Monday, so I’ll try and remember to take some snaps of that one being packed from start to finish …

You must be logged in to post a comment.